-

Cargo Secure equipment

- Special load securing products

- Load securing cardboard

- Lashing straps

- Anti-slip mats and anti-slip underlays

- Load securing material sets for craftsmen

- Ladungssicherung von IBC

- Lashing chains

- Load securing cargo nets

- Blocking devices

- Diagonal lashing equipment

- Tension force measuring devices

- Protractors

- Cargo securing accessories

- Cargo Secure equipment in containers

- Training material

- Lifting equipment

- ADR equipment

- Merchandise articles

- To the homepage

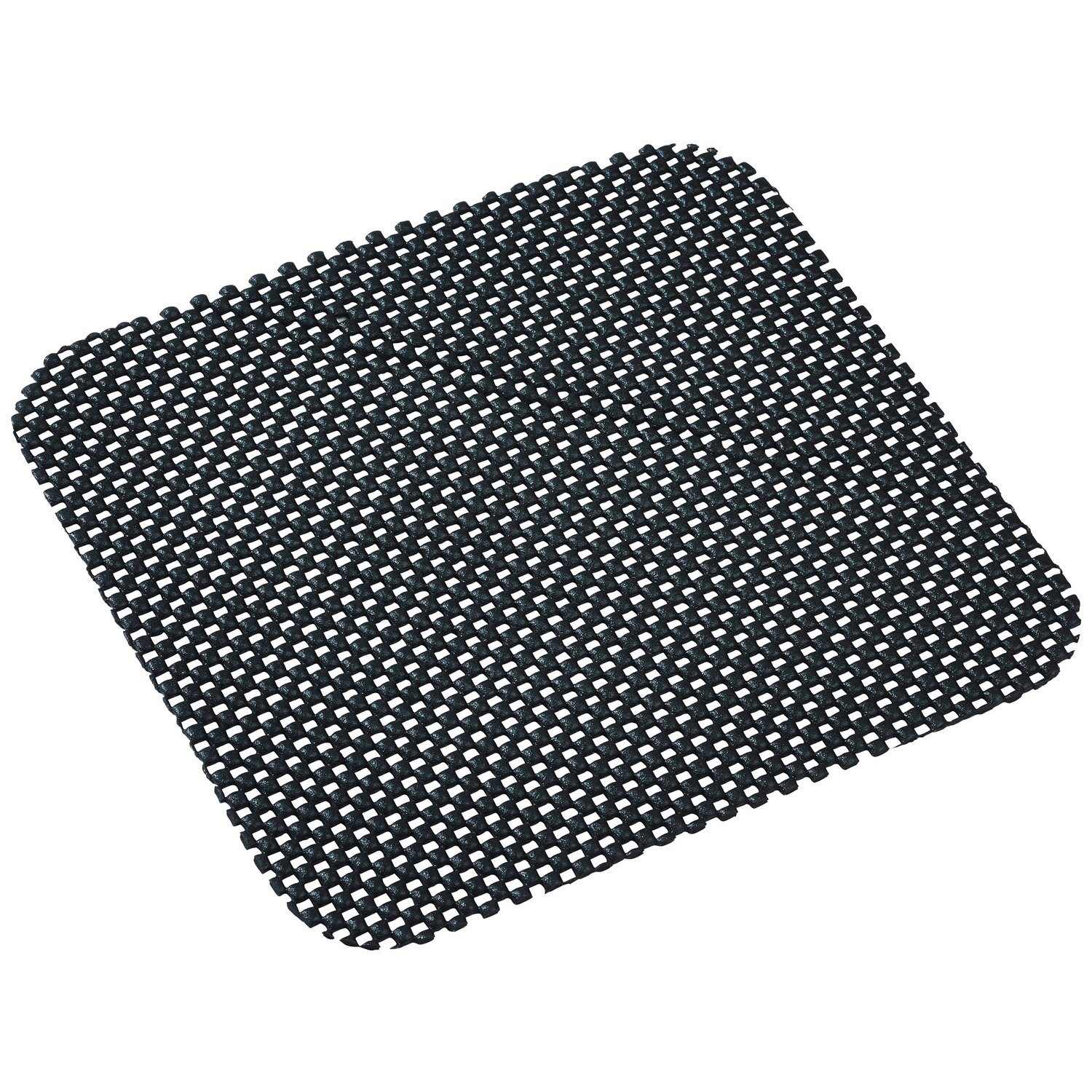

Made of rubber granulateCan be used multiple times, durable, strongPollution TolerantEasy to stow awayOnly 3mm thickMade in Germanyimproves the coefficient of friction up to µ = 0.6

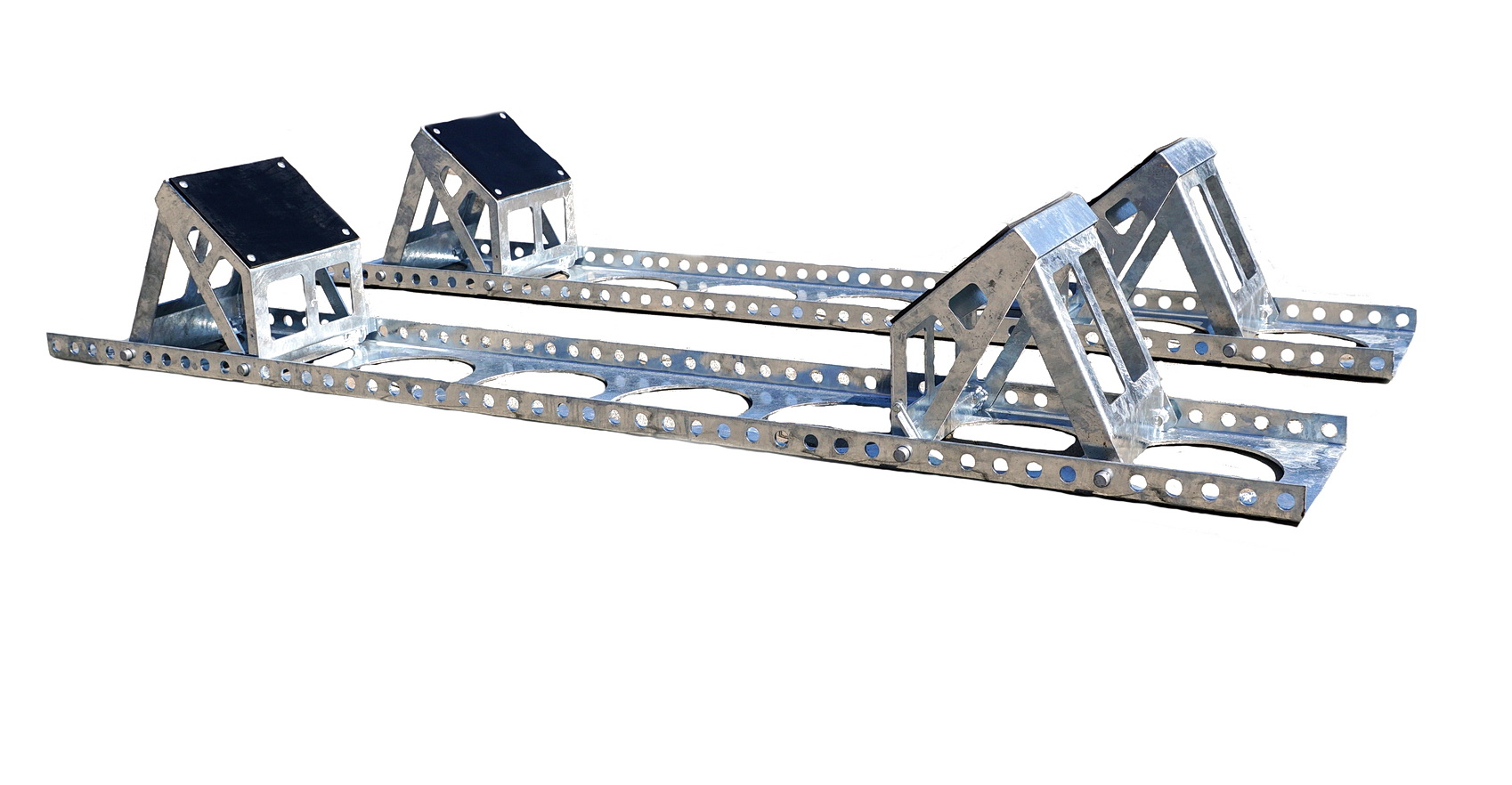

Mit dem GWS®-FlexSis 300 PLUS Rollensicherungssystem können schnell und einfach runde Ladegüter mit unterschiedlichem Durchmesser auf der Ladefläche gesichert und transportiert werden. Das System ist unabhängig von zusätzlichen Sicherungseinrichtungen auf der Ladefläche einsetzbar, man benötigt keine weiteren Löcher oder Sicherungsschienen. Die Ladefläche wird außerdem geschont, da keine Hölzer mehr wie herkömmlich vernagelt werden müssen. Das geringe Gewicht des Systems ermöglicht Ihnen einen einfachen und schnellen Auf- und Abbau. 1 Set besteht aus: 1 x Lochschiene 2x Keil Stützfläche 2 x Keil Auflageflächen mit Anti-Rutsch-Matten, aufgenietet Technische Daten: Traglast einer Schiene bei Rollendurchmesser bis 2.400 mm = 10.000 kg Traglast einer Schiene bei Rollendurchmesser bis 3.000 mm = 8.000 kg Maße: Höhe liegend: ca. 160 mm Höhe stehend: ca. 450 mm Länge der Schiene: 3.000 mmBreite: 360 mm Gesamtgewicht: ca. 58 kgFlyer FlexSis 280 Plus FlexSis Anwendungsbeispiele

Compliance with the specifications of VDI 2700 sheet 15 is observed in the production of these non-slip mats. Grid anti-slip mat flexible tear resistant Only 3.3mm thick Made in GermanyAre you interested in other dimensions?Not sure which mats you need?Give us a call! We would be happy to advise you!

Compliance with the specifications of VDI 2700 sheet 15 is observed in the production of these non-slip mats. Fully flexible and highly tear-resistant Can be used again and again Highest coefficient of sliding friction Easy to store and clean 4.5mm thick Made in GermanyAre you interested in other dimensions?Not sure which mats you need?Give us a call! We would be happy to advise you!

Compliance with the specifications of VDI 2700 sheet 15 is observed in the production of these non-slip mats. Fully flexible and highly tear-resistant Can be used again and again Highest coefficient of sliding friction Easy to store and clean 4.5mm thick Made in GermanyAre you interested in other dimensions?Not sure which mats you need?Give us a call! We would be happy to advise you!

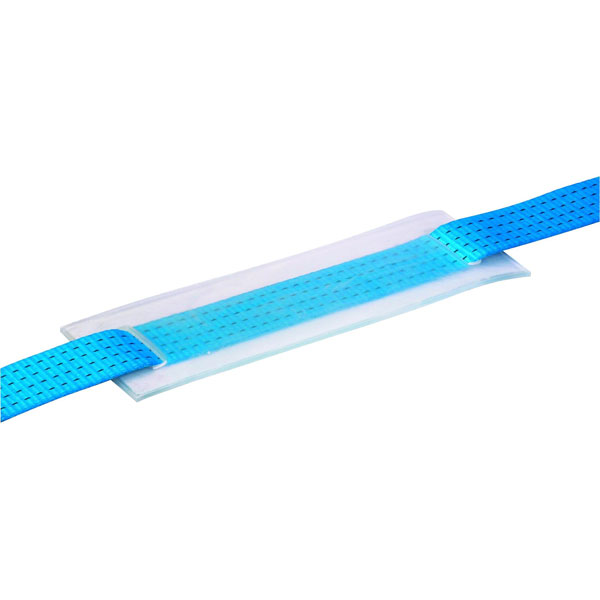

Pulled loosely onto the webbing, protective hoses enable better distribution of the pretensioning forces and protect the webbing from wear.For 75 mm webbing (round slings or lifting straps), cut in 30 cm Better power distribution Longer durability of the lashing straps Protection of the load against abrasion

Reliably protects the webbing across the entire wear zone. As a roll of 50 m each, for 50 mm thick webbing. No slipping Abrasion-resistant materials Better distribution of the preload force Particularly flexible - can simply be rolled up

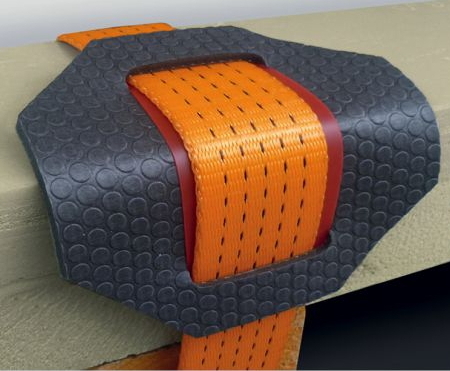

Non-staining edge protection pad with anti-slip effect and sliding body for lashing straps with a strap width of up to 50 mm.Maximum safety thanks to the anti-slip effect and absolutely tear-resistant thanks to the integrated fabric.The convincing advantages at a glance: - handy and light, octagonal 15 x 15 cm - Reduction of the friction loss (“k-value”) at the edges of the load reduces the loss and damage of transported goods -Time savings through possible permanent fixation on the tension belt

The heavy-duty pad that becomes edge protectionWhether the heaviest concrete columns, cast steel parts or large machines - sharp-edged and difficult-to-secure loads are secured against slipping or scratching with the GWS® anti-slip edge protection pad for heavy-duty transport and lashing straps are protected. The convincing advantages at a glance: - Very long service life - Easy to clean again and again - Protects lashing straps and minimises transport damage - Reduces friction loss (‘k-value’) at the edges of the load - Handy and lightweight Dimensions:120 mm x 240 mm x 3 mm

The heavy-duty pad that becomes edge protectionWhether the heaviest concrete columns, cast steel parts or large machines - sharp-edged and difficult-to-secure loads are secured against slipping or scratching with the GWS® - anti-slip edge protection pad for heavy-duty transport and lashing straps are protected.The convincing advantages at a glance: -very long useful life -always easy to clean -protects lashing straps and reduces transport damage -Reduction of the friction loss (“k-value”) at the edges of the load - Handy and lightDimensions:-120mm x 240mm x 6mm

Transporting a single barrel securely with a vehicle still turns out to be a challenge. The GWS® barrel safety device 200 offers the optimal solution because it was specially developed for transporting single 200 liter barrels.The application of the barrel securing remains simple: You simply attach the barrel cross strap to the top of the 200 liter barrel, place the barrel on a non-slip surface and brace the 4 supplied lashing straps diagonally at the lashing points of the vehicle. Your barrels are secured against slipping and tipping!The set consists of:1 x GWS® barrel cross strap 200 made of 35 mm webbing4 x GWS® ratchet lashing strap 1.000 daN, 35 mm webbing1 x GWS® anti-slip mat barrel safety device 200All parts are also available individually!see also:GWS® drum safety device 200 for pallets

Compliance with the specifications of VDI 2700 sheet 15 is observed in the production of these non-slip mats. Improves the coefficient of sliding friction to µ = 0.6 Mats or rolls of rubber granules Maximum load: 250 t/m² = 2.5 N/mm² at 8 mm thickness Tensile strength approx. 0.80 N/mm² based on DIN EN ISO 1798 Elongation at break at least 60% based on DIN EN ISO 1798 Can be used multiple times, durable, strong Pollution Tolerant Easy to stow away Thicknesses: 6mm, 8mm, 10mm Made in GermanyAre you interested in other dimensions?Not sure which mats you need?Give us a call! We would be happy to advise you!

GWS® AT-PAPP is an aid to protect the cargo for your road, rail and sea transport and is very well suited for securing the end of containers.The GWS® AT-PAPP is the newly developed securing aid for the protection and final securing of the load in the container when using TY-GARD 2000® or TY-GARD DS®.When using the TY-GARD® reverse band (headband), this cardboard can also be used very well as impact protection.Distributes the force evenly and protects the load from damageCheaper and easier to handle than e.g. wooden panels or similar.High strength cardboardCan be used multiple times if used correctlyIndividual production—all production dimensions possibleThe GWS® AT-PAPP is fully recyclable and protects the environment.Minimum purchase: 900 piecesSmaller quantities: It is possible to purchase a smaller quantity in connection with other current orders.

The GWS® belt and edge protection is used as a base to protect the lashing strap.Benefits: Handy and easy on the load Longer durability of the lashing straps Better force distribution in the lashing strapAlso available for tape widths of 25, 35 and 75 mm on request

Certified load unit! The GWS® Quick-Lashing 1/600 drum securing system was developed and certified for the stable formation of load units and load securing of a 200 litre steel drum weighing up to 600 kg on a Euro pallet. In the further development of our proven drum securing versions for the safe transport of individual drums, still a challenge from a load securing perspective, we have again focussed on simple and, above all, fast handling.Euro pallet, anti-slip mat, apply the GWS® drum securing Quick-Lashing cross strap and lash with the newly developed GWS® lashing straps. The loading unit is ready! - Suitable for 200 litre steel drums weighing up to 600 kg - Quick and easy to set up - no further aids such as tensioners are required - Designed for resource-saving reusable use - Certified design for forming load units in accordance with DIN 55415:2022 - Classification in transport stability class TK 1 (highest level) according to DIN 55415:2022 in longitudinal and transverse direction - Load unit stability for horizontal acceleration a ≥ 1.0𝑔 in longitudinal and transverse direction facilitates load securing - Use on the road, in combined transport by rail and ship - Use in containers - Suitable for Euro pallets and CP wooden pallets The GWS® Quick-Lashing 1/600 drum lock consists of the following components:Item no. Quantity Item description 222002 1 piece GWS®- Drum securing Quick-Lashing 60-1/600 - Cross strap with all- round one- piece lashing strap made of 35 mm lashing strap fabric 100816-1TH 4 pieces GWS®- Drum securing Quick-Lashing 60-1/600 - Lashing straps, 2-piece with end fitting 160365 1 piece GWS® anti-slip mat made of rubber granulate with friction coefficient µ 0.6 and dimensions 650 mm x 650 mm x 3 mm You will receive a certificate and operating instructions for the load unit with the delivery. With the certification of the GWS® Quick-Lashing 1/600 drum securing system, the load unit can be classified in the highest transport stability class TK 1 in the longitudinal and transverse directions in accordance with DIN 55415:2022. Due to the determined tipping angle and the calculated friction coefficients according to DIN EN 12195-1:2021, which were above µ 1.00, as well as the pallet protrusion of the load carrier to the goods, it is possible to load the tested load unit on the basis of the Euro pallet, e.g. on vehicles according to Code XL (DIN EN 12642) in a form-fit manner. The load units can be labelled in accordance with DIN 55415:2022. Instructions for securing the load units formed with the GWS® Quick-Lashing 1/600 drum securing system In-plant transport - storage of drums on pallets in high-bay rackingTransporters When using vans up to 7.5 t GVW in accordance with VDI 2700 Sheet 16:2009, the coefficients of friction determined are above the minimum acceleration coefficients to be taken into account for normal driving in (max. 0.9𝑔), against (max. 0.5𝑔) and transverse (max. 0.7𝑔) to the direction of travel.Code XL When using Code XL vehicles in accordance with DIN EN 12642, the body can absorb the resulting forces (max. 0.8𝑔) so that the tested load units with Euro pallet load carriers with coefficients of friction of ≥ µ 0.30 for curtainsiders and ≥ µ 0.27 for box bodies fulfil one of the conditions of the Code XL certificates.Use in combined transport: Load on means of transport during rail transportDuring rail transport in accordance with DIN EN 12195-1:2021, the coefficients of friction determined are above the minimum acceleration coefficients to be taken into account for normal driving operations in the longitudinal and transverse directions (max. 1.0𝑔).Cargo on means of transport during sea transport During sea transport in accordance with DIN EN 12195-1:2021 and the CTU Code, the coefficients of friction determined are above the minimum acceleration coefficients in the longitudinal and transverse directions (max. 0.8𝑔) to be taken into account for normal shipping operations in sea areas A-C.If load carriers other than Euro pallets are used that have the stability of the Euro pallet (nailing, wooden slat dimensions, etc.), the friction coefficients determined for the load unit can be adopted. If you have any questions, please do not hesitate to contact us. We will be happy to help you if your requirements are not met by this product.

Certified load unit! The GWS® Quick-Lashing 1/600 drum securing system was developed and certified for the stable formation of load units and load securing of a 200 litre steel drum weighing up to 600 kg on a Euro pallet. In the further development of our proven drum securing versions for the safe transport of individual drums, still a challenge from a load securing perspective, we have again focussed on simple and, above all, fast handling.Euro pallet, anti-slip mat, apply the GWS® drum securing Quick-Lashing cross strap and lash with the newly developed GWS® lashing straps. The loading unit is ready! - Suitable for 200 litre steel drums weighing up to 600 kg - Quick and easy to set up - no further aids such as tensioners are required - Designed for resource-saving reusable use - Certified design for forming load units in accordance with DIN 55415:2022 - Classification in transport stability class TK 1 (highest level) according to DIN 55415:2022 in longitudinal and transverse direction - Load unit stability for horizontal acceleration a ≥ 1.0𝑔 in longitudinal and transverse direction facilitates load securing - Use on the road, in combined transport by rail and ship - Use in containers - Suitable for Euro pallets and CP wooden pallets The GWS® Quick-Lashing 1/600 drum lock consists of the following components:Item no. Quantity Item description 222002 1 piece GWS®- Drum securing Quick-Lashing 60-1/600 - Cross strap with all- round one- piece lashing strap made of 35 mm lashing strap fabric 100816-1TH 4 pieces GWS®- Drum securing Quick-Lashing 60-1/600 - Lashing straps, 2-piece with end fitting 160365 1 piece GWS® anti-slip mat made of rubber granulate with friction coefficient µ 0.6 and dimensions 650 mm x 650 mm x 3 mm You will receive a certificate and operating instructions for the load unit with the delivery. With the certification of the GWS® Quick-Lashing 1/600 drum securing system, the load unit can be classified in the highest transport stability class TK 1 in the longitudinal and transverse directions in accordance with DIN 55415:2022. Due to the determined tipping angle and the calculated friction coefficients according to DIN EN 12195-1:2021, which were above µ 1.00, as well as the pallet protrusion of the load carrier to the goods, it is possible to load the tested load unit on the basis of the Euro pallet, e.g. on vehicles according to Code XL (DIN EN 12642) in a form-fit manner. The load units can be labelled in accordance with DIN 55415:2022. Instructions for securing the load units formed with the GWS® Quick-Lashing 1/600 drum securing system In-plant transport - storage of drums on pallets in high-bay rackingTransporters When using vans up to 7.5 t GVW in accordance with VDI 2700 Sheet 16:2009, the coefficients of friction determined are above the minimum acceleration coefficients to be taken into account for normal driving in (max. 0.9𝑔), against (max. 0.5𝑔) and transverse (max. 0.7𝑔) to the direction of travel.Code XL When using Code XL vehicles in accordance with DIN EN 12642, the body can absorb the resulting forces (max. 0.8𝑔) so that the tested load units with Euro pallet load carriers with coefficients of friction of ≥ µ 0.30 for curtainsiders and ≥ µ 0.27 for box bodies fulfil one of the conditions of the Code XL certificates.Use in combined transport: Load on means of transport during rail transportDuring rail transport in accordance with DIN EN 12195-1:2021, the coefficients of friction determined are above the minimum acceleration coefficients to be taken into account for normal driving operations in the longitudinal and transverse directions (max. 1.0𝑔).Cargo on means of transport during sea transport During sea transport in accordance with DIN EN 12195-1:2021 and the CTU Code, the coefficients of friction determined are above the minimum acceleration coefficients in the longitudinal and transverse directions (max. 0.8𝑔) to be taken into account for normal shipping operations in sea areas A-C.If load carriers other than Euro pallets are used that have the stability of the Euro pallet (nailing, wooden slat dimensions, etc.), the friction coefficients determined for the load unit can be adopted. If you have any questions, please do not hesitate to contact us. We will be happy to help you if your requirements are not met by this product.

Certified load unit! The GWS® Quick-Lashing 1/600 drum securing system was developed and certified for the stable formation of load units and load securing of a 200 litre steel drum weighing up to 600 kg on a Euro pallet. In the further development of our proven drum securing versions for the safe transport of individual drums, still a challenge from a load securing perspective, we have again focussed on simple and, above all, fast handling.Euro pallet, anti-slip mat, apply the GWS® drum securing Quick-Lashing cross strap and lash with the newly developed GWS® lashing straps. The loading unit is ready! - Suitable for 200 litre steel drums weighing up to 600 kg - Quick and easy to set up - no further aids such as tensioners are required - Designed for resource-saving reusable use - Certified design for forming load units in accordance with DIN 55415:2022 - Classification in transport stability class TK 1 (highest level) according to DIN 55415:2022 in longitudinal and transverse direction - Load unit stability for horizontal acceleration a ≥ 1.0𝑔 in longitudinal and transverse direction facilitates load securing - Use on the road, in combined transport by rail and ship - Use in containers - Suitable for Euro pallets and CP wooden pallets The GWS® Quick-Lashing 1/600 drum lock consists of the following components:Item no. Quantity Item description 222002 1 piece GWS®- Drum securing Quick-Lashing 60-1/600 - Cross strap with all- round one- piece lashing strap made of 35 mm lashing strap fabric 100816-1TH 4 pieces GWS®- Drum securing Quick-Lashing 60-1/600 - Lashing straps, 2-piece with end fitting 160365 1 piece GWS® anti-slip mat made of rubber granulate with friction coefficient µ 0.6 and dimensions 650 mm x 650 mm x 3 mm You will receive a certificate and operating instructions for the load unit with the delivery. With the certification of the GWS® Quick-Lashing 1/600 drum securing system, the load unit can be classified in the highest transport stability class TK 1 in the longitudinal and transverse directions in accordance with DIN 55415:2022. Due to the determined tipping angle and the calculated friction coefficients according to DIN EN 12195-1:2021, which were above µ 1.00, as well as the pallet protrusion of the load carrier to the goods, it is possible to load the tested load unit on the basis of the Euro pallet, e.g. on vehicles according to Code XL (DIN EN 12642) in a form-fit manner. The load units can be labelled in accordance with DIN 55415:2022. Instructions for securing the load units formed with the GWS® Quick-Lashing 1/600 drum securing system In-plant transport - storage of drums on pallets in high-bay rackingTransporters When using vans up to 7.5 t GVW in accordance with VDI 2700 Sheet 16:2009, the coefficients of friction determined are above the minimum acceleration coefficients to be taken into account for normal driving in (max. 0.9𝑔), against (max. 0.5𝑔) and transverse (max. 0.7𝑔) to the direction of travel.Code XL When using Code XL vehicles in accordance with DIN EN 12642, the body can absorb the resulting forces (max. 0.8𝑔) so that the tested load units with Euro pallet load carriers with coefficients of friction of ≥ µ 0.30 for curtainsiders and ≥ µ 0.27 for box bodies fulfil one of the conditions of the Code XL certificates.Use in combined transport: Load on means of transport during rail transportDuring rail transport in accordance with DIN EN 12195-1:2021, the coefficients of friction determined are above the minimum acceleration coefficients to be taken into account for normal driving operations in the longitudinal and transverse directions (max. 1.0𝑔).Cargo on means of transport during sea transport During sea transport in accordance with DIN EN 12195-1:2021 and the CTU Code, the coefficients of friction determined are above the minimum acceleration coefficients in the longitudinal and transverse directions (max. 0.8𝑔) to be taken into account for normal shipping operations in sea areas A-C.If load carriers other than Euro pallets are used that have the stability of the Euro pallet (nailing, wooden slat dimensions, etc.), the friction coefficients determined for the load unit can be adopted. If you have any questions, please do not hesitate to contact us. We will be happy to help you if your requirements are not met by this product.

Transporting a single drum secured in a vehicle is still a challenge. The GWS® drum securing device 60 offers the optimum solution, as it has been specially developed for transporting individual 60-litre drums. The drum securing system is easy to use: simply attach the drum cross strap to the top of the 60-litre drum, place the drum on a non-slip surface and tighten the 4 lashing straps supplied diagonally to the lashing points of the vehicle. This secures your barrels against slipping and tipping! The set consists of: - 1 x GWS® drum cross strap 60 made from 35 mm webbing - 4 x GWS® ratchet lashing strap 800, 25 mm webbing - 1 x GWS® anti-slip mat for securing drums 60 Translated with

Certified load unit! The GWS® Quick-Lashing 1/600 drum securing system was developed and certified for the stable formation of load units and load securing of a 60 litre steel drum weighing up to 600 kg on a Euro pallet. In the further development of our proven drum securing versions for the safe transport of individual drums, still a challenge from a load securing perspective, we have again focussed on simple and, above all, fast handling.Euro pallet, anti-slip mat, apply the GWS® drum securing Quick-Lashing cross strap and lash with the newly developed GWS® lashing straps. The loading unit is ready!- Suitable for 60 litre steel drums weighing up to 600 kg - Quick and easy to set up - no further aids such as tensioners are required - Designed for resource-saving reusable use - Certified design for forming load units in accordance with DIN 55415:2022 - Classification in transport stability class TK 1 (highest level) according to DIN 55415:2022 in longitudinal and transverse direction - Load unit stability for horizontal acceleration a ≥ 1.0𝑔 in longitudinal and transverse direction facilitates load securing - Use on the road, in combined transport by rail and ship - Use in containers - Suitable for Euro pallets and CP wooden pallets The GWS® Quick-Lashing 1/600 drum lock consists of the following components:Item no. Quantity Description 220502 1 piece GWS®- Drum securing Quick-Lashing 39-1/600 - Cross strap with circumferential, one-piece lashing strap made of 35 mm lashing strap fabric100816-1TH 4 pieces GWS®- Barrel securing Quick-Lashing 60-1/600 - Guy lashing straps, 2-piece with end fitting160365 1 piece GWS® anti-slip mat made of rubber granulate with coefficient of friction µ 0.6 and dimensions 650 mm x 650 mm x 3 mmYou will receive a certificate and operating instructions for forming the load unit with the delivery. With the certification of the GWS® Quick-Lashing 1/600 drum securing system, the load unit can be classified in the highest transport stability class TK 1 in the longitudinal and transverse direction in accordance with DIN 55415:2022. Due to the determined tipping angles and the calculated friction coefficients according to DIN EN 12195-1:2021, which were above µ 1.00, as well as the pallet protrusion of the load carrier to the goods, it is possible to load the tested load unit on the basis of the Euro pallet, e.g. on vehicles according to Code XL (DIN EN 12642) in a form-fit manner. The load units can be labelled in accordance with DIN 55415:2022. Instructions for securing the load units formed with the GWS® Quick-Lashing 1/600 drum securing system In-plant transport - storage of drums on pallets in high-bay racking. The reusable solution can be used in-house for transport with industrial trucks as well as for storage (in high-bay racking) and increases safety for employees.Load on means of transport during road transport: Transporters When using vans up to 7.5 t GVW in accordance with VDI 2700 Sheet 16:2009, the coefficients of friction determined are above the minimum acceleration coefficients to be taken into account for normal driving operations in (max. 0.9𝑔), against (max. 0.5𝑔) and transverse (max. 0.7𝑔) to the direction of travel. Code XL When using Code XL vehicles in accordance with DIN EN 12642, the body can absorb the resulting forces (max. 0.8𝑔) so that the tested load units with Euro pallet load carriers with coefficients of friction of ≥ µ 0.30 for curtainsiders and ≥ µ 0.27 for box bodies fulfil one of the conditions of the Code XL certificates. Use in combined transport: Cargo on means of transport during rail transport During rail transport in accordance with DIN EN 12195-1:2021, the coefficients of friction determined are above the minimum acceleration coefficients to be taken into account for normal driving operations in the longitudinal and transverse directions (max. 1.0𝑔).Cargo on means of transport during sea transport During sea transport in accordance with DIN EN 12195-1:2021 and the CTU Code, the coefficients of friction determined are above the minimum acceleration coefficients in the longitudinal and transverse directions (max. 0.8𝑔) to be taken into account for normal shipping operations in sea areas A-C. If load carriers other than Euro pallets are used that have the stability of the Euro pallet (nailing, wooden slat dimensions, etc.), the determined coefficients of friction of the load unit can be adopted. If you have any questions, please do not hesitate to contact us. We will be happy to help you if your requirements are not met by this product.

Extremely break-resistant and dimensionally stable thanks to the new design.For the transport of standing, lying or edge-sensitive loads.Suitable for transporting paper rolls.Technical specifications: For webbing width 50 mm High quality technical ABS plastic Extremely break-resistant and dimensionally stable thanks to the new design Improvement of the deflection factor "k" when lashing down to k = 1.8 Belt fixation by side guide Pressure point shifted by raised side parts no edge damage due to cavity inside Dimension 217x187x120mm Weight approx. 318g1 carton = 56 pieces

for strap width 25 mm - Dimension 110 x 70 x 32 mm - Weight: 18 gr.

for strap width 35 mm - Dimension 110 x 70 x 42 mm - Weight: 19 gr.

Extremely break-resistant and dimensionally stable thanks to the new design.For the transport of standing, lying or edge-sensitive loads.Suitable for transporting paper rolls.Technical specifications: For webbing width 50 mm High quality technical ABS plastic Extremely break-resistant and dimensionally stable thanks to the new design Improvement of the deflection factor "k" when lashing down to k = 1.8 Belt fixation by side guide Pressure point shifted by raised side parts no edge damage due to cavity inside Dimension 105x105x90mm Weight approx. 112g1 carton = 200 pieces

This particularly light edge angle protects your load from transport damage and protects your lashing straps. - light and flexible - 135 mm wide, 90 mm leg length - suitable for belts up to 75 mm wide