-

Cargo Secure equipment

- Special load securing products

- Load securing cardboard

- Lashing straps

- Anti-slip mats and anti-slip underlays

- Load securing material sets for craftsmen

- Ladungssicherung von IBC

- Lashing chains

- Load securing cargo nets

- Blocking devices

- Diagonal lashing equipment

- Tension force measuring devices

- Protractors

- Cargo securing accessories

- Cargo Secure equipment in containers

- Training material

- Lifting equipment

- ADR equipment

- Merchandise articles

- To the homepage

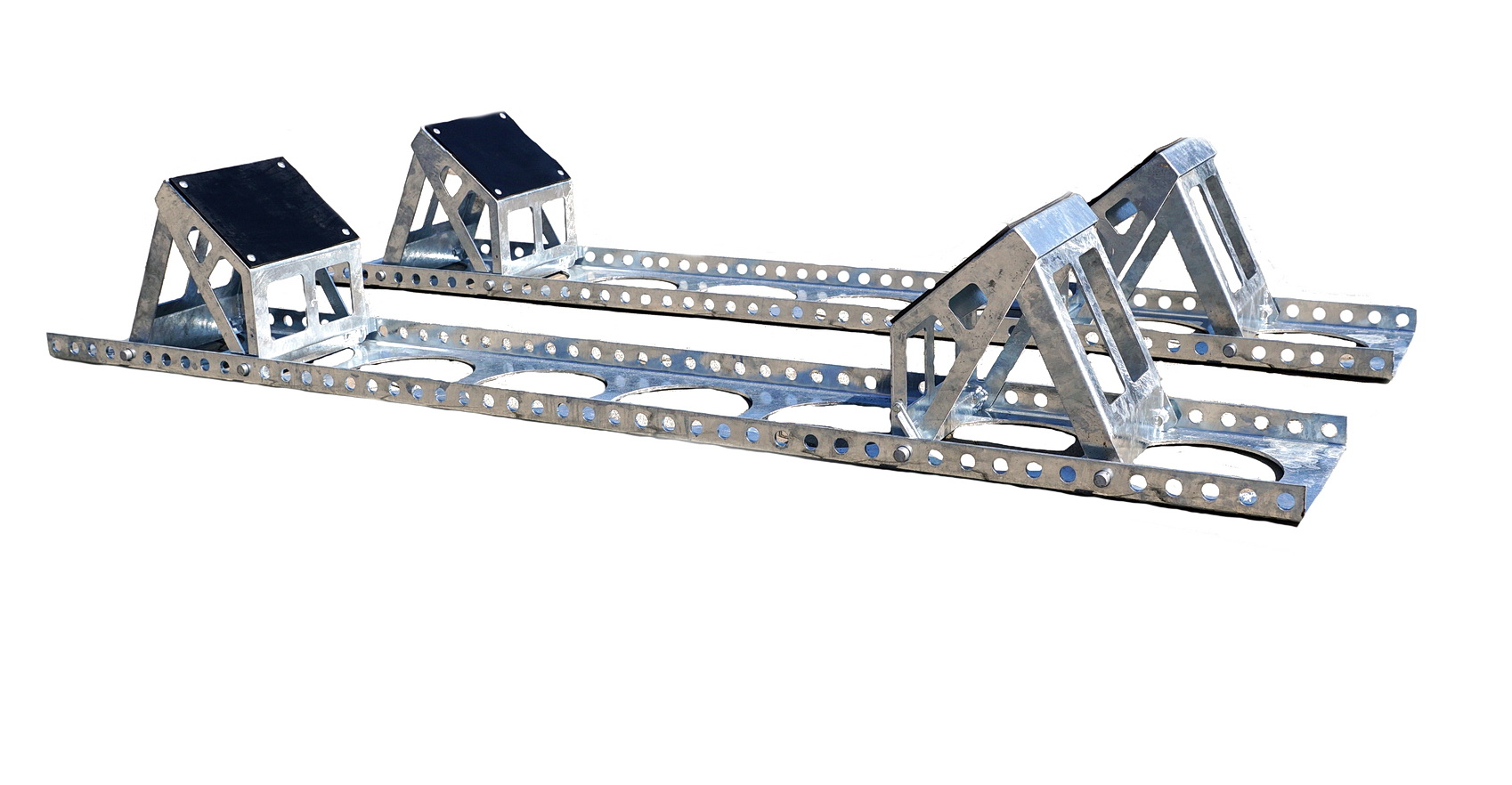

Mit dem GWS®-FlexSis 300 PLUS Rollensicherungssystem können schnell und einfach runde Ladegüter mit unterschiedlichem Durchmesser auf der Ladefläche gesichert und transportiert werden. Das System ist unabhängig von zusätzlichen Sicherungseinrichtungen auf der Ladefläche einsetzbar, man benötigt keine weiteren Löcher oder Sicherungsschienen. Die Ladefläche wird außerdem geschont, da keine Hölzer mehr wie herkömmlich vernagelt werden müssen. Das geringe Gewicht des Systems ermöglicht Ihnen einen einfachen und schnellen Auf- und Abbau. 1 Set besteht aus: 1 x Lochschiene 2x Keil Stützfläche 2 x Keil Auflageflächen mit Anti-Rutsch-Matten, aufgenietet Technische Daten: Traglast einer Schiene bei Rollendurchmesser bis 2.400 mm = 10.000 kg Traglast einer Schiene bei Rollendurchmesser bis 3.000 mm = 8.000 kg Maße: Höhe liegend: ca. 160 mm Höhe stehend: ca. 450 mm Länge der Schiene: 3.000 mmBreite: 360 mm Gesamtgewicht: ca. 58 kgFlyer FlexSis 280 Plus FlexSis Anwendungsbeispiele

Transporting a single barrel securely with a vehicle still turns out to be a challenge. The GWS® barrel safety device 200 offers the optimal solution because it was specially developed for transporting single 200 liter barrels.The application of the barrel securing remains simple: You simply attach the barrel cross strap to the top of the 200 liter barrel, place the barrel on a non-slip surface and brace the 4 supplied lashing straps diagonally at the lashing points of the vehicle. Your barrels are secured against slipping and tipping!The set consists of:1 x GWS® barrel cross strap 200 made of 35 mm webbing4 x GWS® ratchet lashing strap 1.000 daN, 35 mm webbing1 x GWS® anti-slip mat barrel safety device 200All parts are also available individually!see also:GWS® drum safety device 200 for pallets

Certified load unit! The GWS® Quick-Lashing 1/600 drum securing system was developed and certified for the stable formation of load units and load securing of a 200 litre steel drum weighing up to 600 kg on a Euro pallet. In the further development of our proven drum securing versions for the safe transport of individual drums, still a challenge from a load securing perspective, we have again focussed on simple and, above all, fast handling.Euro pallet, anti-slip mat, apply the GWS® drum securing Quick-Lashing cross strap and lash with the newly developed GWS® lashing straps. The loading unit is ready! - Suitable for 200 litre steel drums weighing up to 600 kg - Quick and easy to set up - no further aids such as tensioners are required - Designed for resource-saving reusable use - Certified design for forming load units in accordance with DIN 55415:2022 - Classification in transport stability class TK 1 (highest level) according to DIN 55415:2022 in longitudinal and transverse direction - Load unit stability for horizontal acceleration a ≥ 1.0𝑔 in longitudinal and transverse direction facilitates load securing - Use on the road, in combined transport by rail and ship - Use in containers - Suitable for Euro pallets and CP wooden pallets The GWS® Quick-Lashing 1/600 drum lock consists of the following components:Item no. Quantity Item description 222002 1 piece GWS®- Drum securing Quick-Lashing 60-1/600 - Cross strap with all- round one- piece lashing strap made of 35 mm lashing strap fabric 100816-1TH 4 pieces GWS®- Drum securing Quick-Lashing 60-1/600 - Lashing straps, 2-piece with end fitting 160365 1 piece GWS® anti-slip mat made of rubber granulate with friction coefficient µ 0.6 and dimensions 650 mm x 650 mm x 3 mm You will receive a certificate and operating instructions for the load unit with the delivery. With the certification of the GWS® Quick-Lashing 1/600 drum securing system, the load unit can be classified in the highest transport stability class TK 1 in the longitudinal and transverse directions in accordance with DIN 55415:2022. Due to the determined tipping angle and the calculated friction coefficients according to DIN EN 12195-1:2021, which were above µ 1.00, as well as the pallet protrusion of the load carrier to the goods, it is possible to load the tested load unit on the basis of the Euro pallet, e.g. on vehicles according to Code XL (DIN EN 12642) in a form-fit manner. The load units can be labelled in accordance with DIN 55415:2022. Instructions for securing the load units formed with the GWS® Quick-Lashing 1/600 drum securing system In-plant transport - storage of drums on pallets in high-bay rackingTransporters When using vans up to 7.5 t GVW in accordance with VDI 2700 Sheet 16:2009, the coefficients of friction determined are above the minimum acceleration coefficients to be taken into account for normal driving in (max. 0.9𝑔), against (max. 0.5𝑔) and transverse (max. 0.7𝑔) to the direction of travel.Code XL When using Code XL vehicles in accordance with DIN EN 12642, the body can absorb the resulting forces (max. 0.8𝑔) so that the tested load units with Euro pallet load carriers with coefficients of friction of ≥ µ 0.30 for curtainsiders and ≥ µ 0.27 for box bodies fulfil one of the conditions of the Code XL certificates.Use in combined transport: Load on means of transport during rail transportDuring rail transport in accordance with DIN EN 12195-1:2021, the coefficients of friction determined are above the minimum acceleration coefficients to be taken into account for normal driving operations in the longitudinal and transverse directions (max. 1.0𝑔).Cargo on means of transport during sea transport During sea transport in accordance with DIN EN 12195-1:2021 and the CTU Code, the coefficients of friction determined are above the minimum acceleration coefficients in the longitudinal and transverse directions (max. 0.8𝑔) to be taken into account for normal shipping operations in sea areas A-C.If load carriers other than Euro pallets are used that have the stability of the Euro pallet (nailing, wooden slat dimensions, etc.), the friction coefficients determined for the load unit can be adopted. If you have any questions, please do not hesitate to contact us. We will be happy to help you if your requirements are not met by this product.

Certified load unit! The GWS® Quick-Lashing 1/600 drum securing system was developed and certified for the stable formation of load units and load securing of a 200 litre steel drum weighing up to 600 kg on a Euro pallet. In the further development of our proven drum securing versions for the safe transport of individual drums, still a challenge from a load securing perspective, we have again focussed on simple and, above all, fast handling.Euro pallet, anti-slip mat, apply the GWS® drum securing Quick-Lashing cross strap and lash with the newly developed GWS® lashing straps. The loading unit is ready! - Suitable for 200 litre steel drums weighing up to 600 kg - Quick and easy to set up - no further aids such as tensioners are required - Designed for resource-saving reusable use - Certified design for forming load units in accordance with DIN 55415:2022 - Classification in transport stability class TK 1 (highest level) according to DIN 55415:2022 in longitudinal and transverse direction - Load unit stability for horizontal acceleration a ≥ 1.0𝑔 in longitudinal and transverse direction facilitates load securing - Use on the road, in combined transport by rail and ship - Use in containers - Suitable for Euro pallets and CP wooden pallets The GWS® Quick-Lashing 1/600 drum lock consists of the following components:Item no. Quantity Item description 222002 1 piece GWS®- Drum securing Quick-Lashing 60-1/600 - Cross strap with all- round one- piece lashing strap made of 35 mm lashing strap fabric 100816-1TH 4 pieces GWS®- Drum securing Quick-Lashing 60-1/600 - Lashing straps, 2-piece with end fitting 160365 1 piece GWS® anti-slip mat made of rubber granulate with friction coefficient µ 0.6 and dimensions 650 mm x 650 mm x 3 mm You will receive a certificate and operating instructions for the load unit with the delivery. With the certification of the GWS® Quick-Lashing 1/600 drum securing system, the load unit can be classified in the highest transport stability class TK 1 in the longitudinal and transverse directions in accordance with DIN 55415:2022. Due to the determined tipping angle and the calculated friction coefficients according to DIN EN 12195-1:2021, which were above µ 1.00, as well as the pallet protrusion of the load carrier to the goods, it is possible to load the tested load unit on the basis of the Euro pallet, e.g. on vehicles according to Code XL (DIN EN 12642) in a form-fit manner. The load units can be labelled in accordance with DIN 55415:2022. Instructions for securing the load units formed with the GWS® Quick-Lashing 1/600 drum securing system In-plant transport - storage of drums on pallets in high-bay rackingTransporters When using vans up to 7.5 t GVW in accordance with VDI 2700 Sheet 16:2009, the coefficients of friction determined are above the minimum acceleration coefficients to be taken into account for normal driving in (max. 0.9𝑔), against (max. 0.5𝑔) and transverse (max. 0.7𝑔) to the direction of travel.Code XL When using Code XL vehicles in accordance with DIN EN 12642, the body can absorb the resulting forces (max. 0.8𝑔) so that the tested load units with Euro pallet load carriers with coefficients of friction of ≥ µ 0.30 for curtainsiders and ≥ µ 0.27 for box bodies fulfil one of the conditions of the Code XL certificates.Use in combined transport: Load on means of transport during rail transportDuring rail transport in accordance with DIN EN 12195-1:2021, the coefficients of friction determined are above the minimum acceleration coefficients to be taken into account for normal driving operations in the longitudinal and transverse directions (max. 1.0𝑔).Cargo on means of transport during sea transport During sea transport in accordance with DIN EN 12195-1:2021 and the CTU Code, the coefficients of friction determined are above the minimum acceleration coefficients in the longitudinal and transverse directions (max. 0.8𝑔) to be taken into account for normal shipping operations in sea areas A-C.If load carriers other than Euro pallets are used that have the stability of the Euro pallet (nailing, wooden slat dimensions, etc.), the friction coefficients determined for the load unit can be adopted. If you have any questions, please do not hesitate to contact us. We will be happy to help you if your requirements are not met by this product.

Certified load unit! The GWS® Quick-Lashing 1/600 drum securing system was developed and certified for the stable formation of load units and load securing of a 200 litre steel drum weighing up to 600 kg on a Euro pallet. In the further development of our proven drum securing versions for the safe transport of individual drums, still a challenge from a load securing perspective, we have again focussed on simple and, above all, fast handling.Euro pallet, anti-slip mat, apply the GWS® drum securing Quick-Lashing cross strap and lash with the newly developed GWS® lashing straps. The loading unit is ready! - Suitable for 200 litre steel drums weighing up to 600 kg - Quick and easy to set up - no further aids such as tensioners are required - Designed for resource-saving reusable use - Certified design for forming load units in accordance with DIN 55415:2022 - Classification in transport stability class TK 1 (highest level) according to DIN 55415:2022 in longitudinal and transverse direction - Load unit stability for horizontal acceleration a ≥ 1.0𝑔 in longitudinal and transverse direction facilitates load securing - Use on the road, in combined transport by rail and ship - Use in containers - Suitable for Euro pallets and CP wooden pallets The GWS® Quick-Lashing 1/600 drum lock consists of the following components:Item no. Quantity Item description 222002 1 piece GWS®- Drum securing Quick-Lashing 60-1/600 - Cross strap with all- round one- piece lashing strap made of 35 mm lashing strap fabric 100816-1TH 4 pieces GWS®- Drum securing Quick-Lashing 60-1/600 - Lashing straps, 2-piece with end fitting 160365 1 piece GWS® anti-slip mat made of rubber granulate with friction coefficient µ 0.6 and dimensions 650 mm x 650 mm x 3 mm You will receive a certificate and operating instructions for the load unit with the delivery. With the certification of the GWS® Quick-Lashing 1/600 drum securing system, the load unit can be classified in the highest transport stability class TK 1 in the longitudinal and transverse directions in accordance with DIN 55415:2022. Due to the determined tipping angle and the calculated friction coefficients according to DIN EN 12195-1:2021, which were above µ 1.00, as well as the pallet protrusion of the load carrier to the goods, it is possible to load the tested load unit on the basis of the Euro pallet, e.g. on vehicles according to Code XL (DIN EN 12642) in a form-fit manner. The load units can be labelled in accordance with DIN 55415:2022. Instructions for securing the load units formed with the GWS® Quick-Lashing 1/600 drum securing system In-plant transport - storage of drums on pallets in high-bay rackingTransporters When using vans up to 7.5 t GVW in accordance with VDI 2700 Sheet 16:2009, the coefficients of friction determined are above the minimum acceleration coefficients to be taken into account for normal driving in (max. 0.9𝑔), against (max. 0.5𝑔) and transverse (max. 0.7𝑔) to the direction of travel.Code XL When using Code XL vehicles in accordance with DIN EN 12642, the body can absorb the resulting forces (max. 0.8𝑔) so that the tested load units with Euro pallet load carriers with coefficients of friction of ≥ µ 0.30 for curtainsiders and ≥ µ 0.27 for box bodies fulfil one of the conditions of the Code XL certificates.Use in combined transport: Load on means of transport during rail transportDuring rail transport in accordance with DIN EN 12195-1:2021, the coefficients of friction determined are above the minimum acceleration coefficients to be taken into account for normal driving operations in the longitudinal and transverse directions (max. 1.0𝑔).Cargo on means of transport during sea transport During sea transport in accordance with DIN EN 12195-1:2021 and the CTU Code, the coefficients of friction determined are above the minimum acceleration coefficients in the longitudinal and transverse directions (max. 0.8𝑔) to be taken into account for normal shipping operations in sea areas A-C.If load carriers other than Euro pallets are used that have the stability of the Euro pallet (nailing, wooden slat dimensions, etc.), the friction coefficients determined for the load unit can be adopted. If you have any questions, please do not hesitate to contact us. We will be happy to help you if your requirements are not met by this product.

Transporting a single drum secured in a vehicle is still a challenge. The GWS® drum securing device 60 offers the optimum solution, as it has been specially developed for transporting individual 60-litre drums. The drum securing system is easy to use: simply attach the drum cross strap to the top of the 60-litre drum, place the drum on a non-slip surface and tighten the 4 lashing straps supplied diagonally to the lashing points of the vehicle. This secures your barrels against slipping and tipping! The set consists of: - 1 x GWS® drum cross strap 60 made from 35 mm webbing - 4 x GWS® ratchet lashing strap 800, 25 mm webbing - 1 x GWS® anti-slip mat for securing drums 60 Translated with

Certified load unit! The GWS® Quick-Lashing 1/600 drum securing system was developed and certified for the stable formation of load units and load securing of a 60 litre steel drum weighing up to 600 kg on a Euro pallet. In the further development of our proven drum securing versions for the safe transport of individual drums, still a challenge from a load securing perspective, we have again focussed on simple and, above all, fast handling.Euro pallet, anti-slip mat, apply the GWS® drum securing Quick-Lashing cross strap and lash with the newly developed GWS® lashing straps. The loading unit is ready!- Suitable for 60 litre steel drums weighing up to 600 kg - Quick and easy to set up - no further aids such as tensioners are required - Designed for resource-saving reusable use - Certified design for forming load units in accordance with DIN 55415:2022 - Classification in transport stability class TK 1 (highest level) according to DIN 55415:2022 in longitudinal and transverse direction - Load unit stability for horizontal acceleration a ≥ 1.0𝑔 in longitudinal and transverse direction facilitates load securing - Use on the road, in combined transport by rail and ship - Use in containers - Suitable for Euro pallets and CP wooden pallets The GWS® Quick-Lashing 1/600 drum lock consists of the following components:Item no. Quantity Description 220502 1 piece GWS®- Drum securing Quick-Lashing 39-1/600 - Cross strap with circumferential, one-piece lashing strap made of 35 mm lashing strap fabric100816-1TH 4 pieces GWS®- Barrel securing Quick-Lashing 60-1/600 - Guy lashing straps, 2-piece with end fitting160365 1 piece GWS® anti-slip mat made of rubber granulate with coefficient of friction µ 0.6 and dimensions 650 mm x 650 mm x 3 mmYou will receive a certificate and operating instructions for forming the load unit with the delivery. With the certification of the GWS® Quick-Lashing 1/600 drum securing system, the load unit can be classified in the highest transport stability class TK 1 in the longitudinal and transverse direction in accordance with DIN 55415:2022. Due to the determined tipping angles and the calculated friction coefficients according to DIN EN 12195-1:2021, which were above µ 1.00, as well as the pallet protrusion of the load carrier to the goods, it is possible to load the tested load unit on the basis of the Euro pallet, e.g. on vehicles according to Code XL (DIN EN 12642) in a form-fit manner. The load units can be labelled in accordance with DIN 55415:2022. Instructions for securing the load units formed with the GWS® Quick-Lashing 1/600 drum securing system In-plant transport - storage of drums on pallets in high-bay racking. The reusable solution can be used in-house for transport with industrial trucks as well as for storage (in high-bay racking) and increases safety for employees.Load on means of transport during road transport: Transporters When using vans up to 7.5 t GVW in accordance with VDI 2700 Sheet 16:2009, the coefficients of friction determined are above the minimum acceleration coefficients to be taken into account for normal driving operations in (max. 0.9𝑔), against (max. 0.5𝑔) and transverse (max. 0.7𝑔) to the direction of travel. Code XL When using Code XL vehicles in accordance with DIN EN 12642, the body can absorb the resulting forces (max. 0.8𝑔) so that the tested load units with Euro pallet load carriers with coefficients of friction of ≥ µ 0.30 for curtainsiders and ≥ µ 0.27 for box bodies fulfil one of the conditions of the Code XL certificates. Use in combined transport: Cargo on means of transport during rail transport During rail transport in accordance with DIN EN 12195-1:2021, the coefficients of friction determined are above the minimum acceleration coefficients to be taken into account for normal driving operations in the longitudinal and transverse directions (max. 1.0𝑔).Cargo on means of transport during sea transport During sea transport in accordance with DIN EN 12195-1:2021 and the CTU Code, the coefficients of friction determined are above the minimum acceleration coefficients in the longitudinal and transverse directions (max. 0.8𝑔) to be taken into account for normal shipping operations in sea areas A-C. If load carriers other than Euro pallets are used that have the stability of the Euro pallet (nailing, wooden slat dimensions, etc.), the determined coefficients of friction of the load unit can be adopted. If you have any questions, please do not hesitate to contact us. We will be happy to help you if your requirements are not met by this product.

New product for general cargo handling: GWS® Flat 3000The innovative large pallet (GWS® Flat 3000) with different load securing options to optimize material handling.Goods are now delivered from a central warehouse via intermediate storage to the end consumer. The time factor plays an important role for the customer / end user.For the forwarder, the time factor is determined by the routes, which cannot be changed, and by the turnaround times.The arriving truck has to be unloaded in the handling hall or in the interim storage facility, a large number of individual Euro pallets.The load is then reassembled and the pallets are loaded individually onto the truck that is to be transported onward.This costs time and manpower!In order to save time and personnel and thus costs when handling materials, we have developed a new type of large pallet.This large pallet can be manufactured in different sizes so that it can be used for material transport both on a truck and in a containerThe current maximum size is 3.600 x 2.400 mm. Up to 9 Euro pallets with a maximum total weight of 3000 kg can be pre-stowed, secured and transported on it.The GWS® Flat 3000 has different load securing nets and lashing systems that are new and very easy and quick to use, which are simply hooked into the lashing points of the flat frame. Attached there, they neither disturb the loading nor the unloading process. So they don't have to be taken off or put back on again and again.With the nets, the load can be very easily secured from below with a maximum of 2 people, but possibly also alone. With the newly developed and supplied quick-release straps, the nets are tightened / lashed in such a way that they encompass the cargo stowed on the Flat and thus form a loading unit.The load is thus secured before loading and thus saves the driver this time-consuming activity. With the load securing nets and the firmly bonded anti-slip covering on the pallet and on the underside of the flat, no further load securing is required in the case of a form fit.Using a switch on the flat frame, the rollers on one side of the pallet can be extended using a battery-operated hydraulic system.The GWS® Flat 3000 can then be moved very easily in the transhipment hall with the help of the maneuvering equipment that belongs to the Flat and an industrial truck such as a forklift, electric ant or pallet truck.It can be loaded in this way via a loading ramp or onto the truck with a larger forklift.The advantages of the new large pallet GWS® Flat 3000 at a glance:Up to 9 pallets with a maximum total weight of 3000 kg can be pre-stowed and secured on the GWS Flat 3000.The 9 Euro pallets can be loaded or unloaded in one operation. This means that when the transport vehicle arrives, only 2 or 3 large panels, for example, have to be moved instead of 18 or 27 individual Euro pallets. This shortens the truck's waiting time at the transshipment point.The load is already secured on the large pallet before it is loaded.Further securing on the truck is no longer necessary with a form fit.This saves time and personnel!Videos:Lifting and loweringLoadingPrices on request to info@gws-schlobohm.de

Expansion module for transporting square loads.Compatible with the GWS-FlexSis 280 perforated rail.

With the GWS®-FlexSis 280 PLUS roller security system, round loads with different diameters can be secured and transported quickly and easily on the loading area. The system can be used independently of additional safety devices on the loading area, no further holes or safety rails are required. The loading area is also protected, since no more wood has to be nailed in as is conventional. The low weight of the system enables you to set it up and take it down quickly and easily. The GWS®-FlexSis has been tested and certified by TÜV-Nord and its practical suitability has been confirmed as excellent after road tests.A set (item no. 212801-P) consists of:1 x perforated rail2 x wedge support surface2 x wedge support surface (with anti-slip mats)All parts are also available individually and can be combined with connecting bolts!The "GWS® FlexSis 280 PLUS" is fully galvanizedTested and certified by TÜV Nord!Technical specifications: Load capacity of a rail with a roller diameter of up to 240 cm = 10,000 kg Load capacity of a rail with a roller diameter of up to 280 cm = 8,000 kg Lying height: 145 mm, standing height: 325 mm Rail Length: 2400mm Width: 360mm Weight: 53kg

Das GWS®-FlexSis Transportgestell wurde entwickelt, um den Transport der GWS®-FlexSis Schienen so einfach wie möglich zu gestalten. Es kann bis zu 32 Schienen aufnehmen. Bei der Entwicklung haben wir darauf geachtet, dass das Transportgestell mit einer Diebstahlsicherung ausgestattet ist, um einen Diebstahl der GWS®-FlexSis Schienen zu verhindern. Zudem werden die Schienen im Gestell gesichert, was die Ladungssicherung auf dem Fahrzeug erheblich erleichtert. Das Gestell ermöglicht es Ihnen außerdem, die Schienen bequem mit einem Gabelstapler aus dem Gestell zu entnehmen oder das gesamte Gestell zu verladen. Zusätzlich sind Hebepunkte installiert, sodass das Be- und Entladen auch mit einem Kran problemlos möglich ist. Die Gestelle können außerdem gestapelt werden und greifen dabei ineinander, was den Lagerplatz effizient nutzt und den Transport erleichtert.

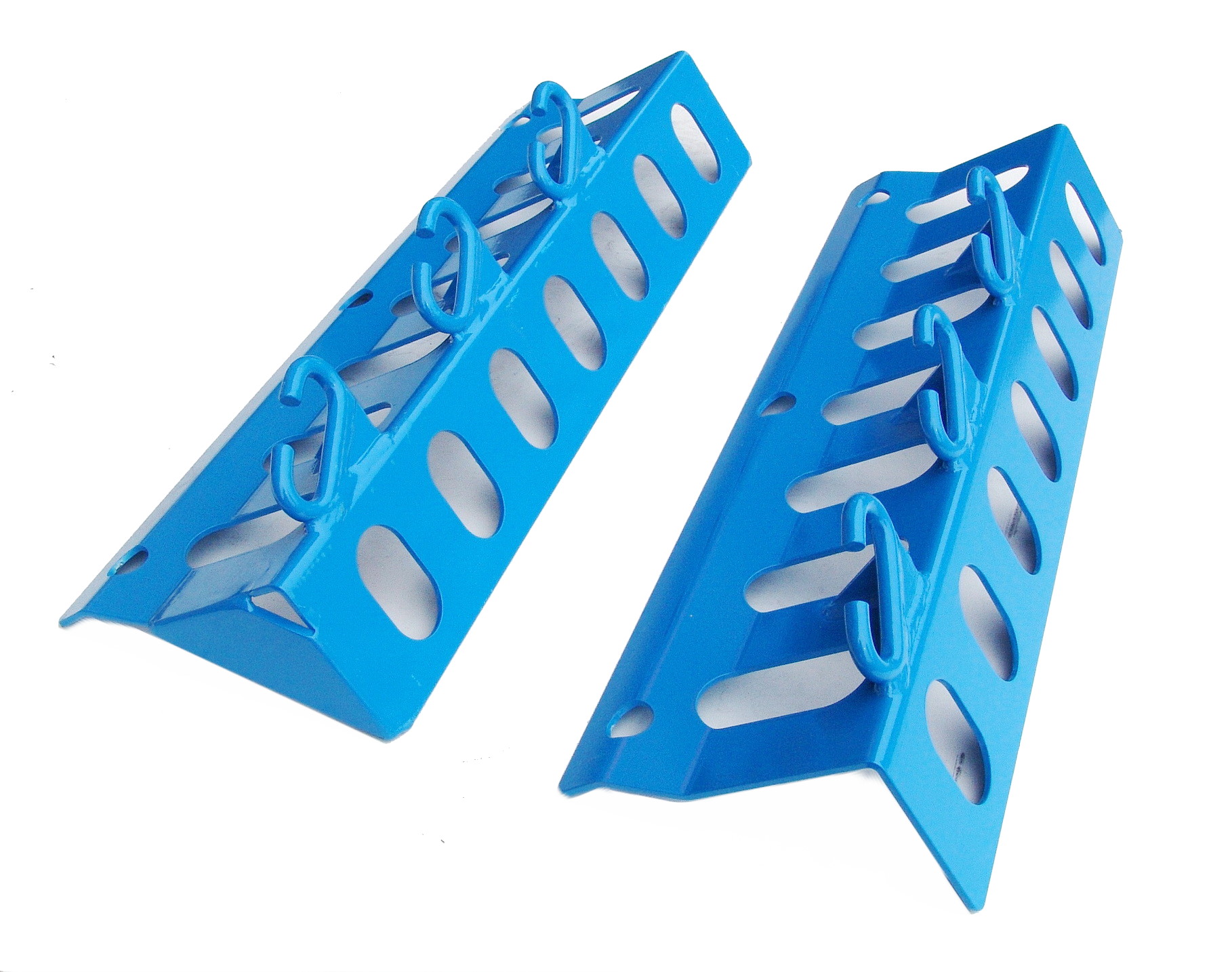

With the heavy-duty GWS® lashing angle for outer edges, you can quickly and easily secure complicated, angular loads using the head lashing method.The GWS® lashing corners can be used independently of additional safety devices on the loading area. Due to the low weight, you can handle it easily and set it up and take it down quickly.left and right lashing angleswith and without cover plateflexible in heightIn road tests, stackable raw chipboard and melamine-coated chipboard weighing up to 24,000 kg could be secured.Technical specifications:Height (standing): 750mmSide length: 120mm x 120mmWeight/pc: approx. 5,8 kg